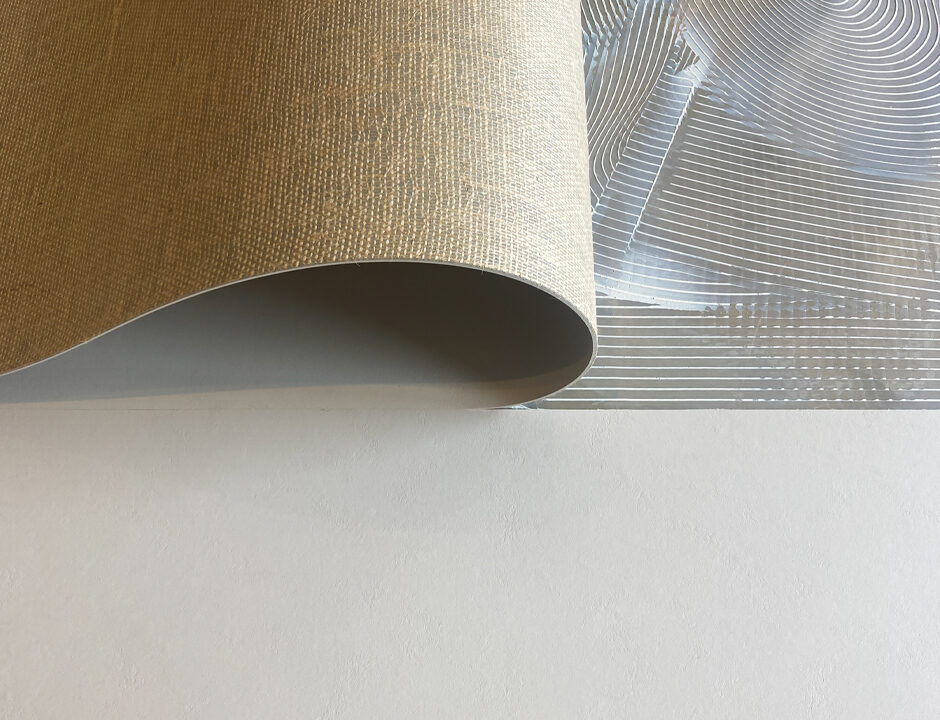

The production story behind this sustainable flooring is a work of art and one you should be aware of…

We are delighted to see our HQ collaboration and social space coming together this month with unique Marmoleum flooring – a linoleum brand by Forbo made from renewable raw materials.

- Linseed oil is pressed from seeds of the flax plant and used as the main ingredient for Marmoleum floors.

- Rosin from pine trees (in controlled forestry locations) is heated together with the linseed oil to create a linoleum paste.

- Finely ground upcycled branches, trunks and roots from trees harvested in the certified forestry industry are added to make the material wood flour.

- Limestone is the fourth element which is added to the linoleum paste mix and the wood flour to create linoleum granules.

- Jute (also known as hessian or burlap) is a vegetable fibre produced from the stalks of the jute plant and is used for the jute mesh carrier on which linoleum is calendered.

- Organic pigments and natural iron oxide take care of the colouration of the granules.

The photosynthesis of the plant-based natural materials used in Marmoleum absorbs more CO2 than is emitted which makes Marmoleum carbon neutral from cradle to gate. This bio-cycle product can be composted and returned to the earth as nutrients for the newly grown natural raw materials.

Installing materials like Marmoleum helps us with our carbon footprint and the lifecycle of our time in our HQ as it’s CO2 neutral (without offsetting) and circular! Read more about the natural production process on their brochure here.