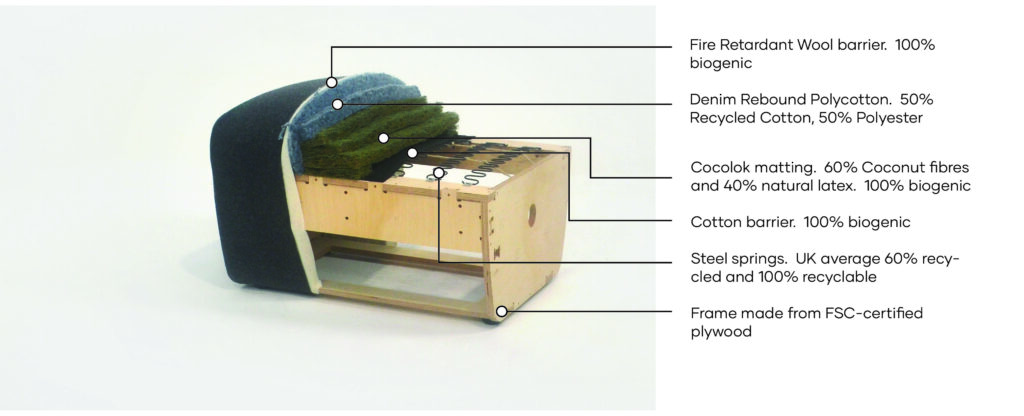

Foam continues to be a bit of an elephant in the room for designers and specifiers – often it is quoted as being a circular product because it can be recycled but in that process it is in fact downgraded – ultimately becoming landfill and is not circular.

For a better future all products need to be circular without degradation of the material.

Despite its many great properties including low cost, comfort and durability, polyurethane foam is problematic for several reasons:

- It is highly flammable and, due to the UK’s unusual ‘match test’ set out in the Furniture &

Furnishings Fire Safety Regulations, usually require toxic flame retardant chemicals. - It is manufactured from unsustainable fossil oil sources.

- It has a high embodied energy and is currently non-recyclable. If treated with flame

retardants, it also poses a health risk to refurbishment operatives. - It off-gasses isocyanates – a respiratory irritant that can trigger asthma attacks.

There have been developments – some products quote that they use plant-based foam but the reality is these alternatives have a small percentage of plant-based content whilst oil remains the majority ingredient.

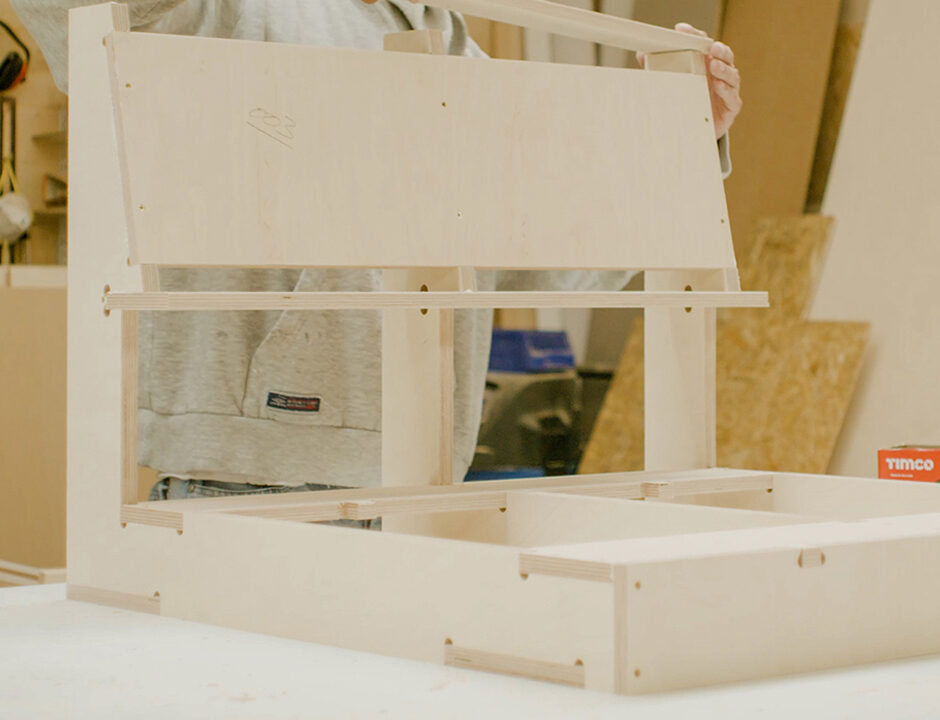

Launching in 2024 our new modular seating system will be entirely free of oil-derived foam. This will see a significant reduction in the products carbon footprint, and a measurable improvement in indoor air quality.

Better for people, better for the planet.